WEDGE WIRE PRODUCTS

WEDGE WIRE PRODUCTS

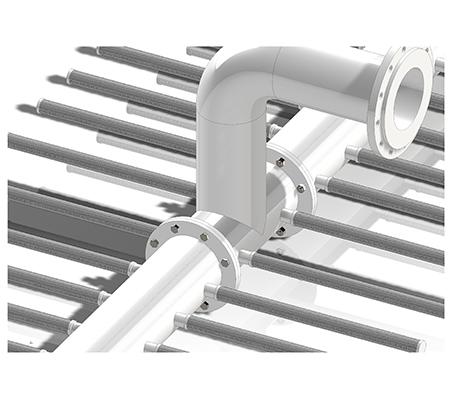

FILTER NOZZLE

The nozzle has a mesh or slotted element with a very particular shape, it consists of very resistant profiles that are usually V-shaped and mounted on different support profiles.

Normally, this V-shaped wire is rolled over these profiles in a circular shape and with a millimetric separation between one and another, this assembly forms a continuous groove that we can call the filtration zone or slotted element.

The V-shaped surface profile usually forms conical grooves that help; if a grain gets stuck between one groove and another, with a little pressure it is easily untied, which avoids a general clogging of the entire nozzle.

Therefore, in its construction it is essential to control this distance between groove and groove very precisely.

Advantages

Effective as a filtration medium, providing media retention.

Diverse selection, supporting custom requirements.

Low pressure drop and high flow rate, ensuring ample water intake.

Simple backwash design

Applications

Sand filters and carbon filters

Condensate polisher and ion exchange systems

Removing impurities in filtration systems in the petrochemical industry

Clarifiers

Underdrains for media filtration

Seawater desalination

Water treatment in thermal power plants