Maintenance Guide: Extending Life of Industrial Filter Elements & Cartridges

Industrial filtration systems are critical in ensuring operational efficiency, product quality, and environmental compliance. Among these systems, filter elements and cartridgesplay a pivotal role in removing contaminants from fluids, gases, and chemicals.

Proper maintenance of these components not only enhances filtration performance but also significantly extends their operational lifespan, reducing downtime and replacement costs.

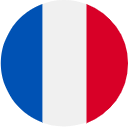

Industrial Filter Elements and Cartridges

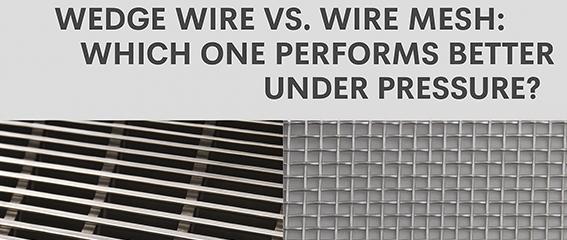

Industrial filter elements and cartridges come in various materials and designs, including stainless steel mesh, wedge wire, and pleated synthetic media. Each type has unique properties suited for specific applications:

• Stainless steel mesh filters: Ideal for high-temperature and high-pressure applications, resistant to corrosion and mechanical wear.

• Wedge wire screens: Offer precise particle retention and are commonly used in water treatment, chemical, and food processing industries.

• Pleated cartridges: Provide high surface area for fine particle removal and are widely used in pharmaceutical and chemical processing.

Choosing the right filter element or cartridge depends on fluid type, operating conditions, particle size, and flow requirements.

Key Maintenance Practices

1. Regular Inspection and Monitoring

Frequent inspection is essential to identify early signs of wear, clogging, or damage. Key indicators include:

• Pressure drop across the filter

• Reduced flow rates

• Visible debris accumulation or corrosion

By monitoring these parameters, operators can prevent system failure and maintain consistent filtration performance.

2. Scheduled Cleaning and Backwashing

Cleaning procedures depend on filter type:

Stainless steel and wedge wire filters can often be backwashed or mechanically cleaned.

Cartridge filters may require chemical cleaning if reusable, or complete replacement if disposable.

Cleaning at regular intervals prevents particle buildup, which can reduce filter efficiency and lifespan.

3. Correct Handling and Installation

Filter elements are sensitive to improper handling. To avoid damage:

• Always wear clean gloves when handling filters.

• Ensure cartridges are properly seated to prevent bypassing or leakage.

• Avoid using excessive force during installation or removal.

• Proper handling reduces the risk of deformation, media damage, or contamination.

4. Optimal Operating Conditions

Filters last longer when operating within their designed specifications:

• Maintain recommended flow rates and pressures.

• Avoid exposing filter media to incompatible chemicals or temperatures.

• Implement pre-filtration for fluids with high solids content.

• Adhering to these guidelines minimizes stress on the filter media and supports consistent performance.

5. Replacement and Lifecycle Management

Even with meticulous maintenance, filter elements have finite lifespans. Implementing a lifecycle management strategy ensures timely replacement:

• Track usage hours and cumulative pressure drops.

• Maintain an inventory of spare elements to minimize downtime.

• Follow manufacturer recommendations for replacement intervals.

A structured replacement plan maximizes system reliability and reduces unexpected failures.

Advantages of Proactive Filter Maintenance

Maintaining industrial filter elements and cartridges provides multiple benefits:

• Extended filter lifespan: Reduces replacement frequency and operating costs.

• Improved process efficiency: Prevents flow restrictions and maintains product quality.

• Reduced environmental impact: Proper disposal and recycling of used elements promote sustainability.

• Enhanced safety and compliance: Reduces risk of contamination in sensitive processes.

Proper maintenance of industrial filter elements and cartridges is essential for long-term performance and operational efficiency. Regular inspection, cleaning, correct handling, optimal operating conditions, and planned replacement together form a comprehensive maintenance strategy. By implementing these practices, industries can ensure reliable filtration, minimize downtime, and extend the life of critical filter components.