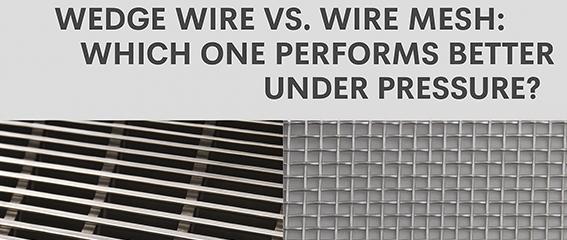

Wedge Wire Screen vs Traditional Mesh: Which is Better for Industrial Filtration?

In industrial filtration, choosing the right screen material is critical for efficiency, durability, and long-term performance. Two of the most widely used options are wedge wire screens and traditional mesh screens.

What is a Wedge Wire Screen?

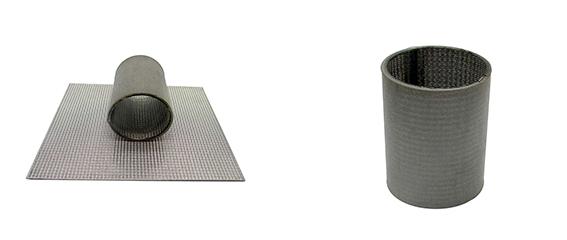

A wedge wire screen, also known as a V-wire screen, is made of stainless steel rods welded in a V-shaped profile over support rods. This design creates a continuous slot that allows liquids to pass while blocking solids. The precision of the slot ensures consistent particle retention and minimizes clogging.

Key characteristics of wedge wire screens:

• Durable construction: Typically made from stainless steel (SS304, SS316, or SS316L), resistant to corrosion and mechanical stress.

• Customizable slot sizes: Can filter particles from a few microns to several millimeters.

• Self-cleaning design: The wedge profile reduces the risk of debris getting stuck, improving flow and reducing maintenance.

• High strength-to-weight ratio: Supports heavy-duty industrial use without bending or warping.

What is a Traditional Mesh Screen?

A traditional mesh screen is usually woven from wire strands to form a grid. Mesh screens have been used for decades in filtration, straining, and separation processes.

Key characteristics of traditional mesh screens:

• Simple design: Woven or perforated wire creates openings for liquid-solid separation.

• Lower initial cost: Generally less expensive than wedge wire screens for basic filtration needs.

• Limited durability: Fine mesh can clog easily and may deform under high pressure or abrasive particles.

• Variable performance: Slot sizes and uniformity may be less precise, affecting filtration consistency.

Wedge Wire Screen vs Traditional Mesh: Performance Comparison

| Feature | Wedge Wire Screen | Traditional Mesh Screen |

| Filtration Precision | High; uniform slot sizes | Moderate; uneven gaps possible |

| Clogging Resistance | Low; self-cleaning profile | High; debris can get trapped easily |

| Durability | Excellent; stainless steel construction | Moderate; fine mesh prone to tearing |

| Maintenance | Low; easier to clean and backwash | High; frequent cleaning required |

| Pressure Resistance | High; suitable for high-flow industrial systems | Limited; may deform under pressure |

| Cost | Higher initial investment | Lower initial cost |

| Lifespan | Long-term, up to 10+ years in harsh conditions | Shorter; may require replacement every few years |

Applications of Wedge Wire Screens

Wedge wire screens are especially suitable for industries that demand high efficiency and low maintenance, such as:

• Water treatment: Intake screens, drum filters, and clarifiers.

• Food and beverage processing: Solid-liquid separation in juices, beer, and dairy.

• Mining and mineral processing: Sand, gravel, and slurry separation.

• Chemical and pharmaceutical industries: Filtration of powders and liquids with high precision.

When Traditional Mesh May Be Sufficient

For operations with low flow, non-abrasive liquids, or cost constraints, traditional mesh screens can still be effective. Examples include:

• Small-scale fluid straining.

• Laboratory filtration setups.

• Temporary filtration applications where frequent replacement is acceptable.

While traditional mesh screens remain viable for simple or low-volume filtration, wedge wire screens are generally superior for industrial-scale, high-demand applications. They deliver more consistent filtration, higher durability, reduced maintenance, and longer service life. Choosing the right material ultimately depends on your filtration requirements, budget, and operational priorities.

For industrial operations looking to optimize efficiency and reliability, wedge wire screens provide a long-term, high-performance solution that traditional mesh screens often cannot match.

Contact us

Email: info@yubofiltration.com

WhatsApp:86 13653285589