Industrial Filtration Trends 2026: Materials, Technologies, and Environmental Regulations

Industrial filtration is undergoing significant evolution as companies worldwide face rising production demands, stricter environmental regulations, and a growing emphasis on sustainability. By 2026, the filtration industry is expected to see notable advancements in materials, technologies, and compliance strategies.

What Materials Are Shaping Filtration in 2026?

The choice of filtration material directly impacts performance, durability, and maintenance. Several key materials are gaining traction:

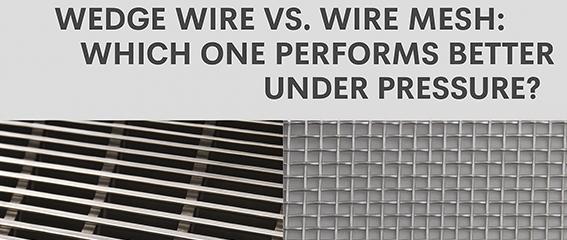

✔ Stainless Steel Wedge Wire and Mesh

Stainless steel (SS304, SS316, SS316L) remains a staple in industrial filtration for water treatment, chemical processing, and mining. Its durability, resistance to corrosion, and high-temperature tolerance make it ideal for high-demand applications.

1. Trends for 2026:

• Increased adoption of V-wire wedge screens for self-cleaning, clog-resistant filtration.

• Hybrid designs combining mesh and wedge wire for tailored flow and particle retention.

2. Advanced Polymers and Composite Materials

Polymeric filters are emerging in industries where chemical resistance and lightweight design are critical. High-performance polymers can withstand aggressive chemicals, reduce system weight, and extend filter lifespan.

3. Applications:

• Food and beverage processing.

• Pharmaceutical production.

• Industrial wastewater treatment.

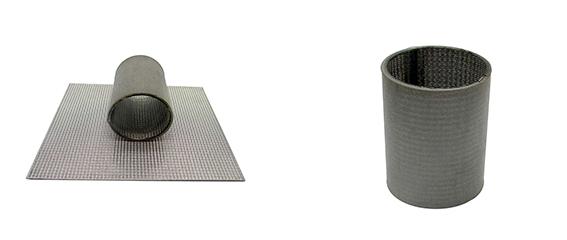

✔ Sintered Metal Filters

Sintered metal wire mesh provides ultra-precise filtration for fine particles. This material is increasingly used in applications where consistent filtration, long lifespan, and high-pressure resistance are required.

What Technologies Are Driving Industrial Filtration Innovation?

Technological innovation is shaping the efficiency and automation of industrial filtration. Key trends include:

• Automated Backwashing and Self-Cleaning Systems

Modern wedge wire and drum filters integrate automated backwashing mechanisms, reducing downtime and maintenance costs. These systems allow continuous operation in high-flow environments.

• Smart Filtration Monitoring

IoT-enabled sensors now allow real-time monitoring of pressure drop, flow rate, and filter saturation. These technologies enable predictive maintenance, reduce operational costs, and improve system reliability.

• Energy-Efficient Filtration Systems

Industrial operators are increasingly prioritizing energy efficiency. Low-pressure, high-flow filtration systems are becoming standard, particularly in water-intensive industries.

How Are Environmental Regulations Shaping Filtration Practices?

Environmental compliance is a critical factor driving filtration technology adoption:

• Water Discharge Standards

Strict discharge limits in Europe, North America, and Asia require high-precision filtration to remove solids, heavy metals, and chemical contaminants before effluent release.

• Waste Reduction and Sustainability

Filtration systems now emphasize minimal waste generation. Self-cleaning screens and reusable filter elements help reduce disposable filter usage and industrial sludge production.

• Chemical Compliance

Industries using aggressive chemicals, such as mining and pharmaceuticals, are adopting corrosion-resistant materials like SS316L and advanced polymers to comply with safety and environmental regulations.

What Industries Will See the Most Impact?

By 2026, industrial filtration trends will significantly influence sectors, including:

• Water treatment and desalination: Efficient, low-maintenance wedge wire screens are critical for municipal and industrial water systems.

• Mining and mineral processing: Durable filtration solutions help manage abrasive slurries and recover valuable solids.

• Food and beverage production: Compliance with hygiene standards and consistent filtration performance is essential.

• Pharmaceutical and chemical manufacturing: Precision filtration and chemical resistance remain top priorities.

The industrial filtration landscape in 2026 will be defined by durable materials, automated and energy-efficient technologies, and strict adherence to environmental regulations. Stainless steel wedge wire screens, sintered metal filters, and high-performance polymers will dominate industrial applications. Meanwhile, smart monitoring and automated cleaning systems will enhance reliability and reduce operational costs.

For companies aiming to stay competitive, investing in advanced filtration technologies and environmentally compliant materials is no longer optional — it is essential for operational efficiency, sustainability, and regulatory adherence.