How to Select the Right Industrial Filter Housing for Water, Chemical, or Seawater Systems

Choosing the correct industrial filter housing is essential for ensuring equipment protection, stable operation, and long-term cost control. Water treatment plants, chemical facilities, and seawater desalination systems all require filter housings that match their specific process conditions.

The following guide summarizes the key factors engineers should evaluate before selecting a filter housing.

1. Identify the Liquid and Its Corrosiveness

The first step in selecting a filter housing is a clear understanding of the medium being treated. Different liquids exhibit different corrosion, temperature, fouling, and particulate characteristics.

✔ Water Treatment Applications

Generally non-corrosive but may contain suspended solids, sand, or organic matter.

Filter housings typically include SS304, SS316L, or coated carbon steel.

Applications include RO pretreatment, cooling water, industrial process water, and wastewater polishing.

✔ Chemical Processing Applications

Often corrosive, reactive, or solvent-based.

Requires accurate selection of corrosion-resistant materials such as SS316L, Duplex stainless steel, Hastelloy, or PTFE-lined housings.

Consider chemical compatibility charts and operational pH ranges.

✔ Seawater and High-Salinity Systems

Highly corrosive due to chloride ions.

SS316L, Duplex (2205), Super Duplex (2507), or specially coated interiors are preferred.

Critical for desalination plants, offshore platforms, seawater cooling, and intake filtration.

Selecting the housing material based on the liquid’s chemistry directly affects equipment lifespan and maintenance cost.

2. Match the Housing to Your Filtration Purpose

Each process requires a specific filtration function:

RO and UF pretreatment: Cartridge or security filter housings

High-solids or fluctuating turbidity: Self-cleaning filter housings

Chemical processing: Pressure-rated, corrosion-resistant housings

Food & beverage: Sanitary stainless steel housings

The filtration objective determines the housing structure, size, and internal element type.

3. Confirm Filtration Accuracy and Element Compatibility

Choose the housing that supports the required filter element:

Cartridge filters (1–50 μm): RO protection, product polishing

Bag filters (10–200 μm): High flow and general-purpose filtration

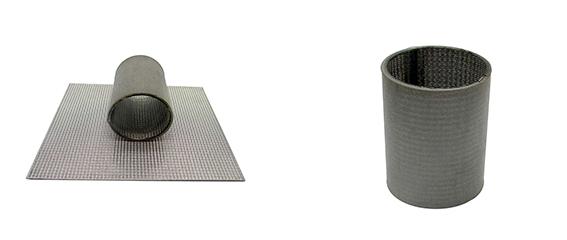

Wedge wire elements: Anti-clogging applications or high-solids systems

Sintered metal elements: High temperature, high pressure, or catalyst recovery

Filtration accuracy should be based on particle size, product requirements, and allowable pressure drop.

4. Check Operating Pressure, Temperature, and Flow Rate

Proper sizing prevents pressure loss and safety risks. Verify:

Maximum operating pressure

Operating temperature

Flow rate (m³/h or GPM)

Viscosity and solids loading

Industrial systems typically require 1.0–3.0 MPa depending on application.

5. Choose the Right Cleaning Method

Maintenance strategy affects long-term cost:

Self-cleaning housings: Best for seawater and high-solids water

Cartridge housings: High accuracy, replaceable consumables

Bag housings: Simple operation and low labor cost

Backpulse housings: High-temperature or catalyst applications

Select the cleaning method that supports your uptime requirements.

6. Ensure Compliance With Industry Standards

Reliable filter housings should follow standards such as:

ISO9001, ISO14001, ISO45001

CE, FDA, ASME

GB/T and drinking water standards for local compliance

Request material certificates, test reports, and quality documentation when necessary.

Choosing the right industrial filter housing requires evaluating the liquid characteristics, filtration purpose, accuracy, operating conditions, and maintenance strategy. When these factors are aligned, the filtration system delivers higher reliability, lower operating costs, and longer service life.

For technical evaluation or customized filter housing design, YUBO's engineering team provides professional consultation and tailored filtration solutions for water, chemical, and seawater applications.